The starting point for nearly all sheet metal fabrication items is blanking; at Rhino Mfg. These machines are capable of holding tolerances of better than 0.005 and can punch parts using over 50 different shaped tools at a time. Using our four CNC press brakes to form complicated three dimensional shapes and features with bends up to 12 feet long.

Speed, accuracy & repeatability are the key to forming; Our brakes regularly hold better than 0.005 tolerances and keep angles within +/- 1/2 degree of nominal. Hydraulic clamping rams and quick change tooling help us to change tools and setup machines in a fraction of the time required by other companies.

Speed, accuracy & repeatability are the key to forming; Our brakes regularly hold better than 0.005 tolerances and keep angles within +/- 1/2 degree of nominal. Hydraulic clamping rams and quick change tooling help us to change tools and setup machines in a fraction of the time required by other companies.

Services

From construction and industrial equipment to the electronics/scientific communities and musical/entertainment field, RHINO has a diverse background in any kind of needs that you might have. We are committed to quality and on-time delivery. Whether you are looking for a long term source for sheet metal fabrication production work or quick-turn prototype product and sheet metal fabrication development; Rhino Mfg. Inc. is your solution.

We believe that business is a community. Customers, Vendors, Employees and Owners. We all work for the benefit of each other, and seek improvement for all through partnership. Everyone at Rhino is servicing our customers. However we have a team of 4 individuals, specifically responsible for servicing customer needs.

The large majority of our fabrications and assemblies begin in the sheet metal or plate form. Solid models are broken down to the component level, flattened out and nested for optimum material utilization. CNC code is created and sent to our blanking equipment. For the ultimate in precision cutting.

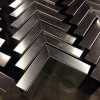

Turning flat and straight parts into 3D (three dimensional) shapes is typically the second step in most of our manufacturing processes. This can come in the form of tube bending, wire bending, roll forming or precision bending sheet metal with press brakes. Precision forming is critical to our customers and our own processes.

Welding is another fabrication skill often referred to as an art. It is certainly a skill that some people never seem to grasp. For most, it is developed and improved over time. Without controls, this means that producing consistent production quality day in and day out is a challenge that needs assistance.

Reviews

Be the first to review Rhino Manufacturing.

Write a Review